In Spring 2025, Finetrack’s Everbreath® Photon Jacket and Everbreath® Photon Pants have undergone a major renewal. Among the updates, one of the most noteworthy innovations is the next-generation water-resistant zipper, AquaGuard® Tightened, developed by YKK Corporation, the world's leading zipper manufacturer, in collaboration with Finetrack.

In this feature, we take a behind-the-scenes look at the development of AquaGuard® Tightened, exploring how this cutting-edge technology enhances water resistance, elevates overall rainwear performance, and marks a potential breakthrough for the outdoor industry.

Nestled along the Sea of Japan, Kurobe City in Toyama Prefecture is home to YKK Corporation’s Kurobe Manufacturing Center, the company’s core product development hub. Among YKK’s 10 global research and manufacturing sites across North America, South America, and Europe, the Kurobe facility serves as the epicenter of innovation, where cutting-edge technologies and advanced product features are developed. It also plays a vital role as a technology transfer hub, ensuring that breakthroughs made here can be seamlessly integrated into YKK’s manufacturing sites worldwide.

One of the many buildings within YKK’s Kurobe Manufacturing Center, this site houses state-of-the-art factories alongside essential amenities like a cafeteria and hospital, ensuring a well-equipped environment for innovation and employee well-being.

Spanning over 330,000 square meters (approximately 82 acres), YKK’s Kurobe Manufacturing Center is vast, resembling a university campus in scale. Among its many operations, the facility houses a zipper manufacturing plant, where fully automated machines hum in rhythm, producing brass zipper sliders with precision.

Each tiny slider undergoes a meticulous quality inspection, scanned by advanced 3D technology to ensure absolute precision and consistency, maintaining YKK’s uncompromising quality standards.

This image showcases samples displayed at an exhibition hall within the facility, as photography inside the factories is prohibited for confidentiality reasons.

Photon Pants have undergone a major renewal. Among the updates, one of the most noteworthy innovations is the next-generation water-resistant zipper, AquaGuard® Tightened, developed in collaboration with YKK.

Reflecting on the development process, So Aikawa, Product Development Manager at Finetrack, shares: "We wanted to create rainwear that offers top-tier waterproof performance without an inner flap. To achieve this, the zipper alone needed to provide sufficient water resistance."

Responding to Aikawa’s request, the team at YKK’s Kurobe Manufacturing Center, where engineers collaborate on new product development, took on the challenge.

Takumi Arai from the Product Development Department recalls the moment inspiration struck for the new water-resistant zipper. While exploring ideas, he found a key insight in the airtight seals of refrigerator doors, designed to keep cold air from escaping. This concept became the foundation for the development of AquaGuard® Tightened.

"When we first received the request for a zipper with higher water resistance, I honestly thought it would be difficult to achieve. Rather than simply trying to increase water pressure resistance, I believed that focusing on sealing or blocking water would be a more effective approach. So, I started looking for inspiration in everyday objects—juice bottle caps, anything that might spark an idea.

Then one night, I grabbed a drink from the refrigerator and shut the door. That’s when it hit me—‘It’s sealed tightly.’ I took a closer look at the rubber gasket along the edge and thought, ‘This is it. This could work.’ That was the first idea that set everything in motion."

However, replicating the complex structure of a refrigerator gasket in a compact zipper design proved challenging. Seeking a solution, Arai consulted experts across various departments at YKK, leading to a series of trials and refinements. After extensive experimentation, the breakthrough finally came—a mechanism where the zipper tapes on both sides press firmly against each other, creating sealing pressure.

This design forms an M-shaped bulge, significantly increasing the contact surface area between the two sides of the zipper. Unlike conventional water-resistant zippers that rely on a narrow, linear seal, AquaGuard® Tightened achieves a broader, more secure surface seal, dramatically enhancing waterproof performance.

This breakthrough led to the creation of AquaGuard® Tightened, a next-generation zipper that redefines waterproofing in rainwear.

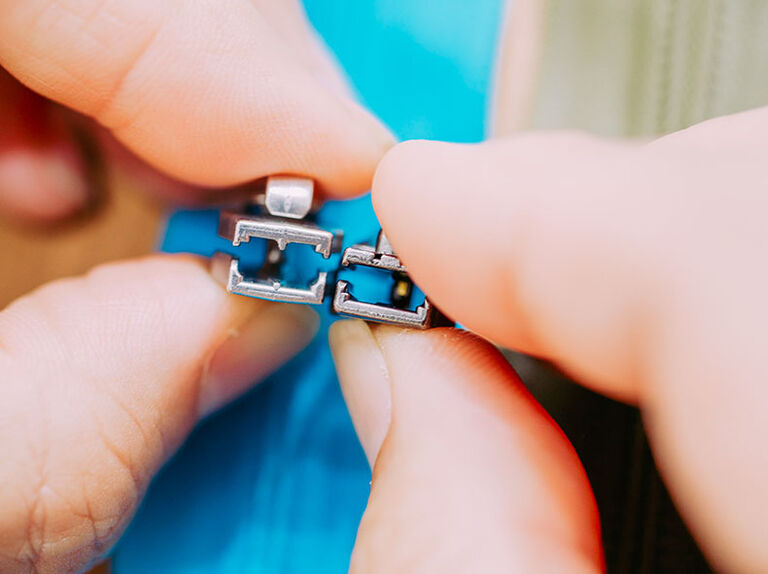

AquaGuard® Tightened on the left, conventional water-resistant zipper on the right.

Of course, countless trials and refinements were made before the final design was achieved. Rei Hironaga from the Slide Fastener Development Department recalls that one of the greatest challenges was perfecting the processing method to create a surface seal similar to a refrigerator gasket.

"To achieve a surface-to-surface seal, we first had to determine the ideal material for the tape. But that was just the beginning. We experimented with countless variables—bending length, thickness, stiffness—testing every possible combination.

The zipper manufacturing process involves various treatments such as heat and color finishing. Initially, we applied heat while the tape was bent, assuming it would retain its shape. However, once the rest of the processing was completed, we found that it had completely lost the necessary sealing pressure. The tapes no longer pressed against each other, leading to a significant drop in water resistance.

We also encountered cases where the tapes overlapped unintentionally, further compromising performance. Even when a prototype performed flawlessly in testing, unexpected issues arose during mass production. It took dozens of prototypes and countless refinements before we finally got it right."

Beside him, Yukako Nakamura from the Product Strategy Division listened attentively, nodding in agreement. With a smile, she said, "The development of the slider also started with handcrafted prototypes, where we tested different shapes to see what might work."

Modifying the slider's shape enables a surface-to-surface seal. The slider on the left, distinguished by its raised central section, is the design used in AquaGuard® Tightened.

"The very first sample was created using lost-wax casting. Since it was just a prototype to explore an idea, the pull tab ended up being nearly three times heavier than the current version—it was so heavy that opening and closing it was a struggle.

The second prototype was significantly lighter, but even then, compared to what we have now, it was still quite heavy." she said with a laugh.

After nearly six years of development and countless prototype iterations since the project began in 2020, AquaGuard® Tightened was finally perfected. This next-generation zipper delivers superior water resistance while eliminating the inner flap, a component traditionally required in conventional water-resistant zippers for additional waterproofing.

Removing the flap was a breakthrough. It prevents the slider from catching on fabric, reducing snags for smoother operation. It also eliminates bulk, creating a sleeker, more flexible silhouette.

To achieve the perfect balance between sliding performance and water resistance, the team meticulously fine-tuned tape thickness, folding position, and zipper fabric weave patterns—refining each element through repeated prototyping to craft the ideal design.

Since its founding, YKK Corporation has remained committed to uncompromising product quality, manufacturing all zipper production equipment in-house. This vertical integration ensures the consistent production of high-quality, reliable zippers, trusted even in the demanding world of mountaineering, where gear must withstand extreme conditions. It also enables YKK to quickly adopt and implement new technologies, driving continuous innovation.

Driven by this relentless pursuit of quality, AquaGuard® Tightened was developed. By integrating this next-generation zipper, the Everbreath® Photon has been elevated to a new standard of rainwear, delivering superior protection and confidence in harsh weather conditions.

We are excited to introduce this innovation and invite you to experience the lightweight comfort and performance of next-generation rainwear.