The Elemental Layer is produced entirely in Japan. Every stage of manufacturing (from thread production and fabric creation to water-repellent processing, dyeing, and final sewing) takes place in specialized factories and workshops across the country. Because every step of production remains in Japan, the Elemental Layer benefits from streamlined communication among these factories, allowing them to collaborate as one cohesive team and fully leverage their professional skills and knowledge to achieve exceptional Japanese quality and craftsmanship from start to finish.

(Nippon Ester Co.: A spinning mill located in Aichi, Japan)

The unique threads used in the Elemental Layer are created inside the tall building visible at the front. Although the interior is a secure area where cameras are prohibited, the production process involves dripping resin from near the ceiling, then cooling and stretching it in a way that resembles spinning spider silk.

The result is polyester “Multi-Profile Irregular Threads” featuring various cross-sectional shapes, including leaf-shaped, triangular, and comb-like. These extraordinary threads stand as a testament to Japan’s world-class textile technology.

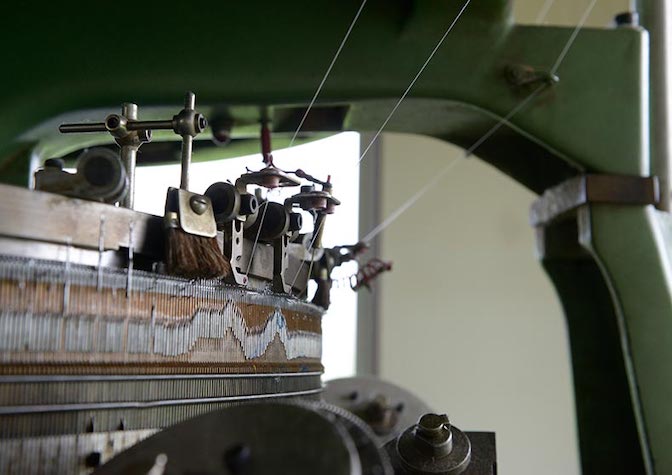

The process of knitting the ultra-thin mesh fabric is highly intricate. To create specialized sweat pathways, the Elemental Layer features “Perforated Mesh” with holes unobstructed by any threads. This specialized textile is produced using a low-gauge circular knitting technique dating back to the 1960s.

Because the method is both rare and antiquated, only a handful of knitting machines across the country can produce it. These machines operate at about a quarter of the speed of standard knitting equipment. As a result, only a few meters of fabric can be made per hour, and even after an entire day’s work, we can produce at most two rolls (about 80 meters in total).

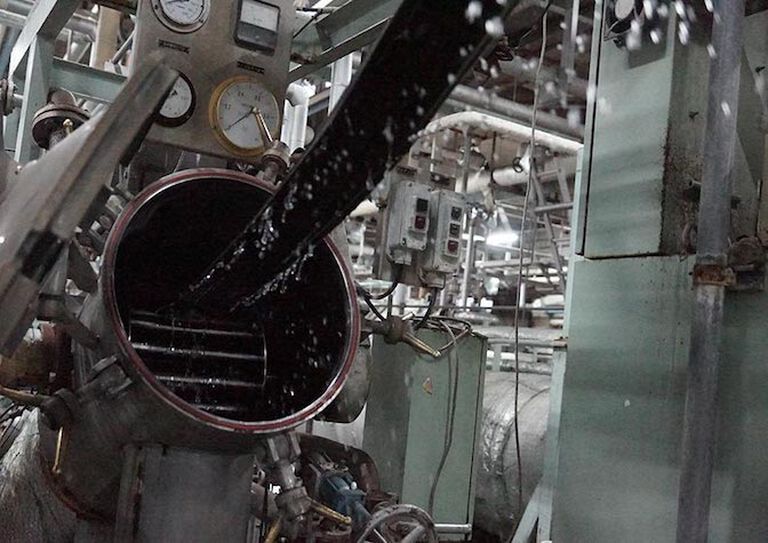

(At the dyeing factory, the fabric, having undergone the dyeing process, is now being removed from the machine.)

The core feature of Elemental Layer, “Durable Water Repellency,” is applied at this state-of-the-art dyeing facility. Inside an approximately eight-meter-long dyeing machine, the knit fabric circulates at high speed while undergoing processing and dyeing.

The DWR standard of 80 points or higher after 150 washes, based on the JIS-L1092 method, indicates that the fabric retains at least 80% of its water-repellent performance even after 150 washes. Achieving such a robust finish without compromising the soft, ultra-thin mesh fabric requires advanced techniques and expertise.

This critical step transforms the hydrophobic polyester knit into an “Elemental Layer (a.k.a. Dry Layer)” that effectively repels sweat and rain. It ensures your skin remains protected from contact with wet garments, helping you stay dry in even the most demanding conditions.

The thickness of the Elemental Layer fabric is just over 0.4 millimeters, making it one of the thinnest possible knit undergarments. Because of this extreme thinness, it cannot be sewn just anywhere. Production is therefore handled by factories with proven expertise, primarily located in western Japan.

One such factory is a small sewing workshop in a port town in Shimane that has been our trusted partner since 2004, dating back to the launch of the world’s first water-repellent undergarment. Their skilled craftsmanship ensures each piece is handled with precision and care.

This is how the Elemental Layer is manufactured entirely in Japan, from thread production and fabric creation to water-repellent processing, dyeing, and final sewing. It is a collaborative effort that draws on the expertise of dedicated professionals who pay close attention to every detail, resulting in a garment that functions as a key element of our outdoor layering system, fully backed by Japanese manufacturing quality and innovation.