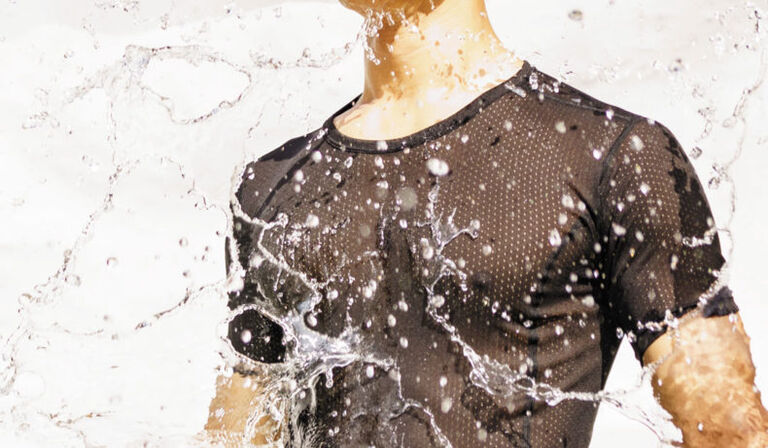

In this second installment of “The Story of Elemental Layer,” we journey into a microscopic world invisible to the naked eye, where the fibers of Elemental Layer threads feature irregular cross-sectional shapes, including leaf-like, triangular, or comb-like forms that vary in both size and contour. These distinctive shapes grant the fabric its impressive water repellency, allowing it to create the signature bead-like water droplets on the mesh surface. Here, we reveal the secrets behind these remarkable irregular threads, an innovation that led to the creation of the world’s first durable water-repellent undergarment.

"A score of 80 points or higher after 150 washes"

This figure reflects the durable water-repellent (DWR) performance of Elemental Layer, measured according to the JIS-L1092 standard. Starting at 100 points, the fabric retains over 80 points of water repellency even after 150 washes, a high specification that justifies its reputation as a “Dry" Layer.

Whether drenched in sweat or soaked by rain, preserving body heat depends on a strong water repellency that endures beyond a few uses or washes. We believed this level of durability was essential for Elemental Layer to be qualified as mountaineering gear.

Traditionally, water-repellent treatments were applied only to woven fabrics, such as those used for backpacks and tents, because adding such treatments to knit fabrics required more advanced techniques. “At the time, the latest DWR technology was just starting to be used on swimwear worn by Olympic-class swimmers to improve their times, so Elemental Layer was a bold attempt to adapt this cutting-edge approach to ultrathin layers,” explains Jun Tanaka from Unichika Trading, who worked with us on the fabric development.

The goal was not simply to coat the fabric’s surface with a water-repellent finish but to ensure every thread repels sweat or rain, keeping skin dry from any moisture. Yet, could DWR processing be applied to such delicate mesh fabric?

Here, irregular threads became the key to making it all possible.

Threads composed of fibers in various sizes and shapes are called “multi-profile irregular threads.” Their protrusions and fine grooves promote capillary action, enabling quick sweat absorption. Under normal circumstances, such fibers are typically used in fabrics with moisture-wicking properties.

However, Elemental Layer turned this concept around by employing these threads for durable water-repellent (DWR) processing, which is essentially the opposite of their original purpose.

Typically, DWR processing involves immersing threads or fabrics in a water-repellent resin. The development team wondered if irregular threads, with their protrusions and indentations, would offer a larger surface area for the resin to adhere to, making it more durable and less likely to peel off. This structure was considered ideal for ensuring thorough coverage and enhancing the water-repellent finish.

At the same time, Unichika Trading had already discovered how multi-profile irregular threads could improve water-repellent durability, according to Mr. Tanaka. The alignment of the development team’s intuition with the manufacturer’s expertise led to the creation of the world’s first DWR undergarment.

Meeting the “80 points after 150 washes” standard was a challenging process. “Multi-profile irregular threads are costly,” Tanaka explains. “At one point, we tried to achieve the 80-point standard after 150 washes using standard, round-profile threads to reduce costs. We produced decent prototypes and handed them to testers without mentioning the change. Almost immediately, Finetrack reported, ‘This feels different. It’s not the same.’ I still wonder how they figured it out. From that moment on, there was no substitute for multi-profile irregular threads.”

Even when some prototypes cleared the numerical threshold, the difference in dry comfort feeling was unmistakable. In the pursuit of the ultimate dry feeling, irregular threads proved to be the only choice for Elemental Layer.